8 Fundamental Truths About Tech Prototyping

In recent years, the ability to print a prototype from a 3D printer has been a boon to many businesses. Perhaps the tech industry has benefited the most from these advances, including the ability to create rapid prototypes until a product is perfect.

Experts predict that 3D printing and additive manufacturing will usher in the fourth industrial revolution. According to Statista, the global 3D printing market will hit $50 billion by 2025. The ability to build functional prototypes for your high-tech goods results in faster concept-to-market speeds.

However, there are some things to keep in mind when it comes to prototypes of tech-related items. Remembering these eight fundamental truths about tech prototyping will save you time, money and frustration.

1. 3D Printers Are More Affordable Than Ever

Industry experts predict 3D printing will turn an eye toward production because of reduced costs. The good news for smaller companies is that the cost of purchasing a prototyping printer is quite affordable. You can easily print a single part to see how it performs in your product, as well as if design changes will improve the item in ways you prefer.

2. Feedback Is Instant

One aggravation designers contend with is developing the perfect working concept only to discover the client doesn't like some small aspect of the creation. The great thing about prototypes is that you can run a sample and get instant feedback from your client and other team members. Doing this saves time in the back-and-forth communication of the design process.

3. Waterjet Cutting Allows for Precision Work

One issue with printing your own components, however, is that the cut isn't always precise. Tech products need a clean cut to avoid any problems with moving parts. Metal waterjet cutting services are perfect for custom parts that need fine detail and intricate cuts. It's a must if working with thicker pieces of metal. Waterjet cutting is also faster and less expensive than some other methods and has minimal tooling costs.

4. It's Easier to Check for Design Flaws Before Manufacturing

Your prototype is an opportunity to test for flaws in your merchandise before going to mass manufacturing. You'll save money on retooling and you won't risk putting out something that fails. For products with moving parts, utilize the sample for durability testing. You should test the item in all the environments and ways the typical customer would use it.

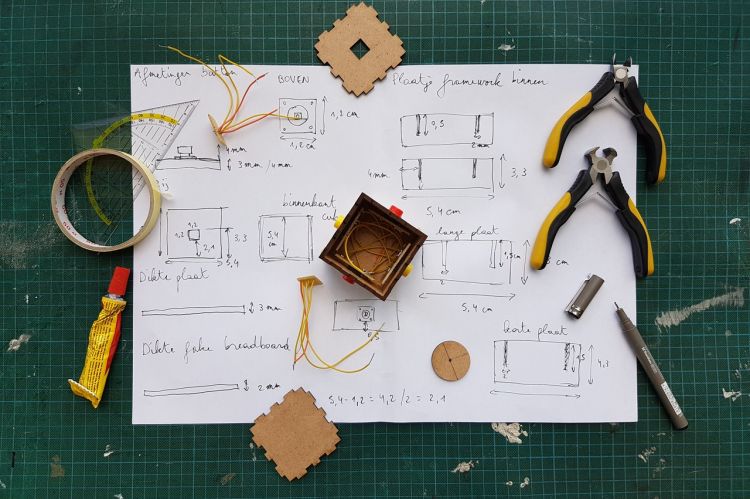

5. Paper Prototyping Still Has a Place

Even though it's inexpensive and easy to print out a 3D model today, there is still a place for paper prototyping in the early stages of the design process. Putting your ideas down on paper is a creative strategy. Digital prototype tools let you see computer-aided designs (CAD) and try out different ideas for almost zero dollars.

As you narrow down the choices, you can then take the form to paper and sketch out the idea in more detail. Many designers start on paper and then transfer the final design to the computer to create a three-dimensional image. They can then generate the form using the 3D printer and adjust it as necessary.

6. It Allows You to Discover How Successful a Product Might Be

Prototypes also enable you to conduct market tests and see whether or not the finished design works for your customer base. For example, if you're planning to create a gadget that helps in a particular industry, you can have workers test the prototype in the field and offer feedback on what they like and dislike.

Survey those who try your product to find out if they'd purchase it and at what price point. This type of market analysis helps take your business from floundering to flourishing with just a little extra effort. You may have several items in development at one time, and such testing allows you to see which experiments are worth producing and which ones should go on the back burner.

7. Custom Designs Create Opportunities for More Business

You may find that some goods can be customized. One example of this type of customization is something as simple as Apple etching names on the backs of their devices. However, you may also change the color, size or other elements of an item. Prototype technology allows you to create a custom design for a single client for an affordable price.

There may also be times when you get a custom order from a school or large corporation, and they want a slightly different addition than your offering typically has. You can test out the add-on and ensure it meets the customer's needs while still being functional.

8. You Can Produce Proprietary Software Your Competitors Don't Have

Many tech services look similar. Imagine a cloud services company — each one offers similar things. But what if you could create something unique that gives your clients feedback on how well their databases are performing or creates more detailed reports than any other business?

Of course, you'd want to make sure the coding is perfect, and ensure the software functions precisely as you expect before offering it to your customers. Rapid prototyping allows you to test everything and make sure it performs as you'd like.

The Next Phase of the Tech Industry

No matter what type of tech company you run, prototyping can help you take it to the next level. From customized products to better software to goods that function at optimum capacity, samples let you test everything thoroughly and ensure you meet clients' needs.